Lithium Ion battery and alumina

Applications for High Purity Alumina in Lithium-ion Batteries

Neal White

Introduction

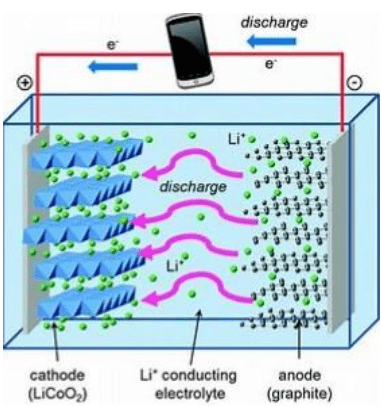

Lithium-ion batteries (LIB) are the

ubiquitous global choice for rechargeable

battery applications, including mobile

phones, Electric Vehicles (EV) and Energy

Storage Systems (ESS). They have been in

production since the 1990’s and

improvements in safety and performance

are continuously being made. Energy

density has increased at around 3% per

year and has now reached approximately

300Wh/kg and 750Wh/l. Despite this

improvement more capacity and longevity

is required to meet the ever-increasing

power demands of the mobile

communication devices and EV

applications. In particular, it is increasingly

important to maximise the cycle life and

minimise the capacity fade of the cells –

this will increase the cumulative capacity

and lifetime of the cells. This in turn

reduces the requirement for new raw

materials to supply the increasing demand

for batteries.

Despite their global usage, current LIB

systems are not fully stable due to

phenomena such as reactions of the

solvents with the anode, cathode structural

changes with cycling, loss of elements from

the cathode compounds, decomposition of

the electrolyte salts and others.

High Purity Alumina (HPA) can play a role in

several crucial aspects of the LIB system to

enhance safety, decrease anode and

cathode degradation reactions and

increase cell lifetime. HPA can be applied to

the battery separator and as coatings on

the graphite (and silicon graphite

composites) anode and on the cathode.

This report will highlight a brief description

of the application of HPA to these three

areas of the cell and the afforded benefit.

AEM addresses this application through the

operation of a clean process run on 100%

renewable energy, certified (pending)

according to ISO9001, 14001 and 45001,

with minimal processing additions –

hydrochloric acid is the only process

chemical, which is recycled from the latter

steps of the process.

A purified secondary product – aluminium

chloride hexahydrate (ACH) is also

produced. The process ensures no foreign

metallic inclusions or transition metal

compounds are present in the product.

HPA as a battery separator coating

A typical lithium-ion battery contains a separator.

LIB separators are essential for the safe and

effective functioning of the cell. They have specific

properties and must be engineered to meet strict

criteria of strength, pore size, thermal resistance,

lithium-ion conductivity etc.

LIB systems are required to be stable and retain

capacity over many cycles of oxidation/reduction

and years of operation, for this reason they

require the use of high purity materials to ensure

adequate performance and safety. Safety issues do

not always manifest during production testing and

may only become apparent themselves after many

cycles of operation. LIBs are susceptible to the

formation of dendrites which can lead to several

problems within the cell, such as a simple loss of

capacity and cycle life for soft short circuits and

severe local heating due to hard shorts, which in

turn can lead to thermal runaway and fire.

The two primary conditions for the formation of

dendrites in lithium-ion batteries is provided as

follows:

a. Deposition of metallic lithium on the

graphite surface on overcharge,

deposition on the graphite of other,

Transition Metals, from the electrolyte

solution under normal charge/discharge

conditions.

b. Transition metals leaching from conventional alumina can be a further source of dendrite initiation, which can be mitigated by high purity alumina, creating a strong value proposition for 4N and 5N products.

In addition to the issue of metal deposition and the formation of dendrites the impact of sodium impurity on the function of LiB is problematic. Traces of sodium can affect the cell capacity and cycle life by its influence on the Solid Electrolyte Interface – SEI- by causing it to thicken and increase in resistance. The AEM process yields very low sodium impurities due to the omission of the sodium hydroxide commonly used in the Bayer process for alumina production.

The application of alumina to the separator as a thin coating confers several performance and safety benefits to the cell.

b. Transition metals leaching from conventional alumina can be a further source of dendrite initiation, which can be mitigated by high purity alumina, creating a strong value proposition for 4N and 5N products.

In addition to the issue of metal deposition and the formation of dendrites the impact of sodium impurity on the function of LiB is problematic. Traces of sodium can affect the cell capacity and cycle life by its influence on the Solid Electrolyte Interface – SEI- by causing it to thicken and increase in resistance. The AEM process yields very low sodium impurities due to the omission of the sodium hydroxide commonly used in the Bayer process for alumina production.

The application of alumina to the separator as a thin coating confers several performance and safety benefits to the cell.

HPA coating for Graphite and Silicon/graphite composite anodes

High purity (4N) graphite is the long-established

anode of choice for LIB. Graphite is widely used

because of its layered structure, high lithium

insertion capacity (372 mAh/g,) high reversibility,

and low cost. In addition, the low potential for Li

insertion produces a high cell voltage, but the fastcharging capability is limited due to the potential

for lithium plating on overcharge.

Anode capacity degradation is partially because of

the reactions between the organic solvents of the

electrolyte and the graphite. The solvent reacts with the anode, forming solid or liquid layer at the

graphite surface, the Solid Electrolyte Interface

(SEI). This results in an irreversible capacity loss

seen on the first cycle. This SEI layer is permeable

and allows transport of ions from the electrolyte

to the graphite surface. The thickness of the SEI

will increase with time which increases the

impedance of the interface and the overpotential

of ions, so it will grow over time, which further

deteriorates the battery and its life span. Failure of

the graphite anode is due to the reduced reaction

rate leading to power fade in batteries and

capacity loss.

One of the methods to mitigate the degradation of

the anode capacity loss is the coating on the anode

particles with alumina. This has the effect of

reducing the contact of the graphite surface with

the electrolyte. This in turn cuts down the reaction

of the electrolyte components with the graphite

and prevents the loss of electrolyte, the build-up

of a thick and increasing SEI. The alumina layer

should be thin, in the order of a few nanometres,

to ensure lithium-ion transport is not impeded.

The alumina should be high purity so as not to add

any problematic elements to the system.

Improvements in cell performance such as a

reduction in irreversible capacity loss and

increased cycle life have been reported.

Battery manufacturers have very strict purity

requirements for graphite to be used in LIB

anodes. A typical purity level is 4N+. To ensure the

overall purity level of the cell system is

maintained, AEM is developing an easy high purity

alumina coating method for graphite using a 4N+

pre-cursor which can be applied at scale and low

cost.

Silicon and silicon/graphite composite anodes also

require protection from degradation via

electrolyte reactions and excessive expansion of

the silicon, which leads to increased surface area,

reaction with the electrolyte and isolation of the

particles from the bulk material and current

collector. In a similar way to the graphite only

anode an alumina coating can protect the silicon

from the electrolyte and increase the lifetime of

the anode. The silicon and silicon/graphite

composite can be treated in a similar process

currently under development by AEM.

HPA coating for LIB Cathodes

Lithium-ion battery cathodes are dominated by

layered lithium metal oxides and

predominately lithium nickel manganese cobalt

oxides (NMC) with varying proportions of Ni

Mn and Co. The industry is moving to high

nickel materials and is reducing the cobalt

content. The high nickel NMC compounds have

good initial capacity, but nevertheless suffer

from degradation during cycling. The loss of

capacity is predominately a result of surface

chemical changes which results in delithiation

and loss of oxygen and a destabilised crystal

structure. A volume change can also take place

which induces cracks in the cathode particles

which exposes more cathode surface to the

electrolyte. In a similar manner to the graphite

the cathode aids the decomposition of the

electrolyte and may lead to surface films and

the production of HF from the

hexafluorophosphate salt. The resulting HF can

dissolve cathode material further degrading

the performance of the cell.

Surface coating of the cathode particles is a

mitigation method to reduce the cathode

surface interacting with the electrolyte.

Coating the cathode powder also helps to

prevent the structural changes in the NMC

material and reduces the microcracking of the

particles. All these mitigations contribute to

increased capacity and cycle-life of the NMC.

Several oxide materials have been investigated

for cathode coating and alumina has been used

successfully by several methods: vapour

deposition, solution and dry mechanofusion

application methods to reduce degradation and improve performance. The coating

thickness is dependent on the porosity of the

coating. Continuous dense locating layers

should be restricted to a few nm to be an

effective barrier without degrading the cell

performance. Porous, more particulate coating

can be several tens of nm thick and give good

results.

As a working hypothesis the mechanism of

protection is primarily surface blocking by the

alumina. Hence, a good, but not complete,

coverage of the cathode particles is required to

affect the long-term improvement in

performance. Ideally, the coating should be an

electronic insulator, and slow down cathode

dissolution without impeding lithium ion

transport to any significant extent.

Electrochemical evaluation of optimized

coatings shows a significant enhancement in

rate performance and capacity retention by

the optimal amount of coating material, while

the solid electrolyte interface (SEI) and charge

transfer impedance is decreased. Coating

weight of around 1 wt% appears to provide the

best results for alumina coated NMC

electrodes.

In a similar manner to the graphite coating

above the cathode coating material should at

least match the purity of the cathode

compound which is normally synthesised from

4N+ precursors.

Similar to the graphite situation, cathode

purity is closely controlled and tightly specified

to be produced from 4N precursor materials.

AEM is currently developing a cathode coating

process where the alumina is formed on the

surface of the cathode particles from a 4N+

precursor