Particle size determination in metal oxides

A Lens to the Nanoscale - Precision Measurement of Ultrafine Particles

Belkacem El Idrissi, Analytical Lab Manager at AEM Canada

Introduction

The characterisation of high purity alumina (HPA) particles

is principally achieved through wet laser diffraction particle

size analysis, a technique capable of providing excellent

insight into the particle size distribution (PSD), typical

known as D10, D50 and D90 fractions, of alumina in either

powder or slurry form.

The choice of measurement technique often depends on the end user’s requirements. It is very important for the recipient to determine their application and needs in terms of particle size distribution; either wet or dry. This will help us to identify the most suitable method that best represents the target application.

The choice of measurement technique often depends on the end user’s requirements. It is very important for the recipient to determine their application and needs in terms of particle size distribution; either wet or dry. This will help us to identify the most suitable method that best represents the target application.

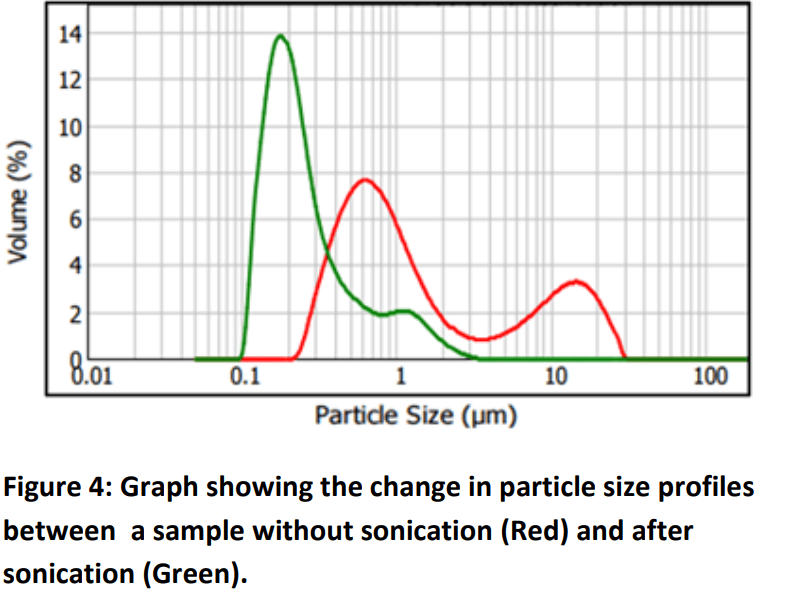

The typical challenge in the determination of particle size is

linked to the fact that fine particles tend to agglomerate,

like in Fig. 1, and stick to each other via Van der Waals

bonding; which means they are relatively easy to break into

smaller particles via non-intrusive agitation methods such

as sonication. This means that sometimes the operator

measures the size of the agglomerates and not the primary

size of the particles. The measurement of the true particle

size dimensions by laser diffraction can present a number

of challenges, in particular interpreting the different results

obtained by different characterisation techniques or

methods (SEM imaging) or particle size distribution (PSD)

measurements in a coherent manner. This article will

address the main difficulties associated with measuring

alumina agglomerates by laser diffraction (wet route)

during the process of wet grinding, drying of the alumina

suspension and dry re-grinding of the clogged alumina to

the size desired by our customers. ‘

Challenges in Measuring the PSD of Sub-micron Alumina Agglomerates:

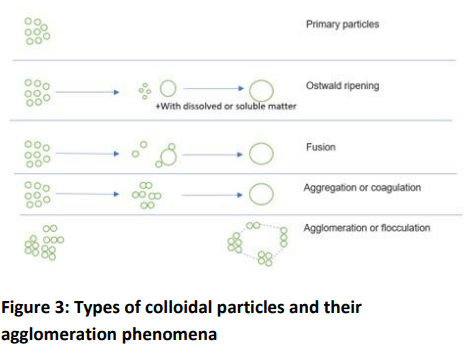

As said before. the distribution and size of finely ground

alumina particles is often affected by the presence of

agglomerates, linked to ripening, aggregation or

agglomeration phenomena. Agglomeration of alumina

nanoparticles can have a significant impact on PSD results.

Understanding these phenomena and controlling the

complete and uniform dispersion of solid particles will

enable us to determine whether additional dispersive

energy (agitation, heating, sonication, etc.) is required to

obtain representative results for the product. Otherwise

there is a risk of obtaining erroneous distribution results,

i.e. an overestimate of particle size and/or an

underestimate of the number of fine particles in the

sample.

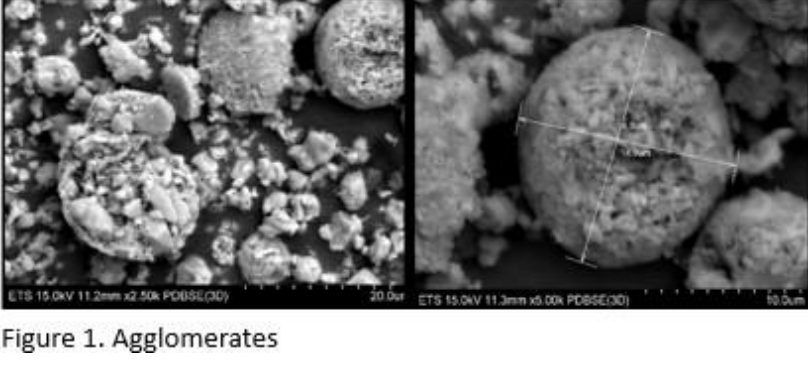

In order to choose the right measurement method, it is

very important to take SEM or optical microscope images to

qualitatively characterise the shape of the particles and to

assess the rate and type of agglomeration of the alumina

particles (Figure 2). It should be noted that SEM is a

qualitative technique that in no way provides reliable

statistics or results on particle size. It is therefore essential

to use a suitable technique to measure the size distribution

of fine particles or nanoparticles (submicron alumina). The

process of agglomeration is very complex and it is

summarized in Figure 3.

Ripening – A phenomenon which depends on the solubility

of alumina in water. Smaller particles have a tendency to

present more surface deformation, resulting in higher

surface energy and increased solubility. The preferential

solubility of small particles will be greater than that of

larger particles. Over time, the population of small

particles will dissolve in solution. The dissolved part of the

small particles will then be deposited on the larger

particles, and the alumina particles will become larger. This

process is known as Ostwald ripening.

Aggregation – Primary particles can come into contact,

sticking together to form strong chemical bonds over a

small area or point of contact. The mechanism is called

aggregation or coagulation. Aggregates of very small or few

primary particles can still be found in the colloidal size

range. Because of the bonds between the primary

particles, they are usually quite difficult to separate using

simple techniques such as stirring, heating or sonication.

Agglomeration – Agglomeration is a phenomenon whereby

fine alumina particles adhere to each other to form larger

particles by means of intermolecular bonding and are often

measured as a single larger particle. Unlike individual

smaller particles that form agglomerate, this type of

agglomeration is generally easy to break up by simple

means such as agitation, heating or sonication.

Agglomeration of fine particles can also affect the shape

and size distribution of particles.

A primary particle is the smallest identifiable subdivision in

a particulate system. Primary particles can stick together to

form “soft/fragile” (easily dispersed) or “hard” (fused)

agglomerates.

The stability of a colloidal system or suspension depends on a number of factors including pH, ionic strength, temperature and the ‘history’ of the dispersion, because in many suspensions the colloid ‘remembers’ its history from the primary particle.

Finely ground metal oxides, and more specifically alumina, are materials that tend to form agglomerates, which means that individual fine particles can come together to form larger structures.

The stability of a colloidal system or suspension depends on a number of factors including pH, ionic strength, temperature and the ‘history’ of the dispersion, because in many suspensions the colloid ‘remembers’ its history from the primary particle.

Finely ground metal oxides, and more specifically alumina, are materials that tend to form agglomerates, which means that individual fine particles can come together to form larger structures.

The agglomeration of metal oxides particles can be caused

by several factors, such as the physio-chemical

characteristics of the surface of fine alumina particles (pH,

conductivity, etc.), electrostatic forces, Van der Waals

forces (attraction and repulsion), micronisation (grinding)

and certain storage conditions can also make these

particles (generally <10 µm in size) more likely to absorb

small quantities of water. This can lead to partial

dissolution at the surface of the metal oxide particles – in

the case of alumina particles, water-soluble aluminium

hydroxide species are formed. Fine particles in contact with

each other can fuse completely or partially to form what

are known as hard or brittle agglomerates. Hard

agglomerates cannot be easily separated without fracturing

the newly formed assembly of individual particles, unlike

brittle agglomerates, which are easier to break up with

sonication or agitation (simple or vigorous).

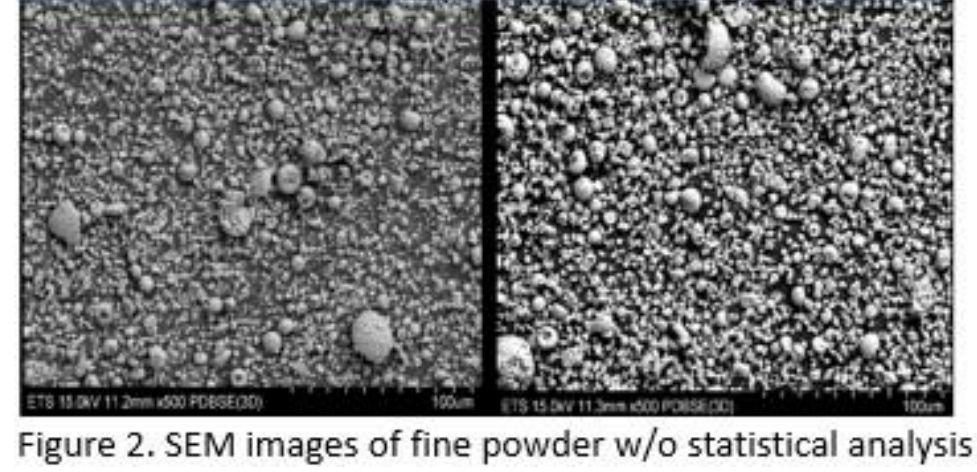

However, it is important to point out that most of the

aggregates that are observed at industrial level are easy to

break. In this regard, figure 4 shows a powder with

aggregates that are quickly broken into the constituent

particles after a quick sonication.

Conclusion

The key to obtaining reproducible and representative

results of particle size distribution by wet laser diffraction is

to prepare a good, stable dispersion of the particle

suspension (colloidal system).

A well-dispersed suspension is a colloid in which the

minimum particle size has been reached and operationally

defined by a constant (minimum) particle size distribution.

This results in complete de-agglomeration of the metal

oxide suspension particles (wet process), which will enable

us to obtain identical or similar results with or without

sonication.

If the addition of a surfactant, mechanical agitation or

heating is not sufficient to separate the fragile

agglomerates, ultrasonic energy can be applied.

A time study using ultrasound can be useful to determine

the sample preparation parameters when fragile

agglomerates are present and when they do not reflect the

main objective of the particle size analysis, we can crosscheck internal methods with other orthogonal techniques

such as:

– Particle size analysis using DLS (Dynamic Light Scattering)

– Centrifugal liquid sedimentation analysis (CLSA)

– Particle Imaging Analysis (PIA) to accurately measure the

particle size distribution of agglomerated particles.

– Nanotrac Nanoparticle analyser.