Sapphire:

The black

sheep of the

watch industry

Richard Foster and Daniele Fregonese of Advanced Energy

Minerals, alongside Frederic Falise of Scientific Visual SA, discuss

the sustainability of sapphire – an important material in the watch

industry

EVERY time you look at your watch, you are taking

advantage of the properties of sapphire without

noticing them. Sapphire is important in our everyday

life because of its transparency and imperviousness

to scratches. In addition to watch covers, it is used in

large volumes for applications from LED substrates

to scratchproof windows for military vehicles.

A sizeable quantity of sapphire is used to make

jewellery and watches, where high-end consumers

are growing conscious of the sustainability of the

products they buy. They would rather buy well-made

products that last and maintain their value than

cheaper goods they would have to throw away after

a short time.

Industrially produced synthetic sapphire is as

hard as natural sapphire but more transparent

because it lacks the trace elements that give gems

their various hues. Sapphire is often marketed as

‘scratch resistant’ or ‘virtually scratchproof’. This

is because it measures nine on the Mohs scale of hardness, meaning that it can only be scratched by

a harder substance such as diamond, which is rated

at ten. (1)

The industrial process to manufacture and customise

sapphire takes place in three major steps. The

first step is to manufacture the high-purity alumina

(aluminium oxide, called HPA). The second step is

to crystallise this HPA at very high temperatures, of

around 2,050°C, to form a raw crystal of synthetic

sapphire. In the third step, this crystal mass is

shaped and sliced into pieces with diamond-coated

saws. The resulting wafers are then ground and

polished for the desired application.

These processes cause a substantial carbon

footprint that we may not think about until we

are made aware of it. For instance the total

crystallisation step (second step) generates

43Kg CO2 per kg of sapphire produced.

However, it can be reduced substantially by

careful attention to each step.

Producing HPA

Manufacturing HPA starts with a mineral feedstock. If

this feedstock is manufactured only with hydropower,

its only carbon footprint at the gate of the factory

where HPA is manufactured is from the transportation.

If the source is close to the factory, this can be

minimal or even brought to zero by compensation.

This is the case for Advanced Energy Minerals (AEM)

which manufactures HPA in Québec, Canada. It uses

feedstock from Québec that is produced predominantly

with hydropower.

The AEM factory was designed to minimise power

consumption by using a patented chlorine leach

crystallisation process. Local renewable sources,

hydro and wind from Hydro Quebec, provide AEM’s

power. The factory at Cap-Chat is the neighbour of

Le Nordais wind park with 133 turbines. Currently,

renewables are at 96%, with specific plans to reach

100% by the end of the year. This will reduce CO2

emissions from the current value of less than two

tonnes of CO2 per tonne of HPA to practically zero.

This is in strong contrast to those using the

traditional alkoxide process, typically non-renewably

powered, which emits 12.3 tonnes of CO2 per tonne

of HPA. Other producers have a goal of reducing this

by a factor of five, which is still very high.

Customisation to meet customer requirements

makes the following process steps more efficient.

AEM has a product line to deliver customised 4N and

5N compacted alumina to its customers. This ranges

in size from pucks of a few grams to giant pucks of

up to 21kg.

HPA to sapphire

The processes to convert HPA to sapphire all melt

the alumina at a temperature above 2,050°C. This is

followed by a slow cooling process that takes one to

two weeks to create a crystal of sapphire. Because

this is a low-tech process, the crystal is not perfect.

It can, however, be influenced by the quality of the

HPA used and the dexterity of the furnace operator.

Lower-purity HPA is used for LEDs. The next level

of purity finds application in watch covers. The

highest quality HPA is transparent to deep UV due

to its low titanium content. This makes it suitable

for medical applications. Crystallisation issues may

also impact the final product quality and determine

the final application. For instance, an LED device

containing an imperfect and inhomogenous sapphire

component may experience decreased efficiency, a

shorter lifespan, or a variation in emission colour. (3)

In addition to HPA quality, the different sapphire growing processes yield crystals that are suitable for different applications. For these reasons, the processes divide here. We have chosen a case study from the Swiss watch industry that shows the environmental benefits of attention to detail. The worldwide watch market of $71bn in 2022 has an expected CAGR of 5%. (4) In particular, it is an important economic driver in Switzerland, where watch exports total almost $25bn. (5) To fulfil this demand, 21 million watch covers are manufactured each year to high-quality standards in Switzerland. (There is also a huge market for smart watches manufactured in Asia that have crystal sapphire covers.) As we shall see, the remaining processing multiplies the environmental costs of the previous steps.

In addition to HPA quality, the different sapphire growing processes yield crystals that are suitable for different applications. For these reasons, the processes divide here. We have chosen a case study from the Swiss watch industry that shows the environmental benefits of attention to detail. The worldwide watch market of $71bn in 2022 has an expected CAGR of 5%. (4) In particular, it is an important economic driver in Switzerland, where watch exports total almost $25bn. (5) To fulfil this demand, 21 million watch covers are manufactured each year to high-quality standards in Switzerland. (There is also a huge market for smart watches manufactured in Asia that have crystal sapphire covers.) As we shall see, the remaining processing multiplies the environmental costs of the previous steps.

Sapphire crystals for watch covers are traditionally

grown with the Verneuil process. The result that

awaits further processing is called a ‘carrot’ in the

trade. It is close to a cylinder in form, approximately

15cm high and 3-4cm in diameter.

Of course, this step has a typical energy requirement

if not performed with green energy. The relevant

CO2 emission would be an average of 89g/kWh for

Switzerland or 475g/kWh worldwide.

Sapphire to watch cover

Because the crystal sapphire carrot has an imperfect

form and contains defects, there will be substantial

yield loss during the further processing steps.

This loss can be minimised by generating a digital

model of the carrot that is based on a 3D scan with

specialised confocal tomography equipment.

It is worth noting that cutting and polishing sapphire

is highly energy-consuming, as the material’s

exceptional hardness presents a significant

challenge

The first step with yield loss is the scrapping of

carrots after inspection and before further processing

due to an unacceptable rate of defects. This has

typically averaged 10% for carrots from the Verneuil

process. Grinding the remaining carrots to the

correct core size and shape produces a form factor yield of 42%. The yield

of cores is then 87%,

meaning that 13% of

cores that reach this

point are thrown away

because of small defects

in the crystal sapphire.

The yield from slicing

the core into wafers and

polishing them is 85%.

The result is an average

combined yield of 28%

in the watch industry

for a flat watch cover.6

This will have a diameter

ranging from 25-45mm

and a thickness from

1.6-6mm. The typical

weight is 4.6g.

The yield means dividing the incoming environmental cost by 0.28, which almost quadruples it. For a domed watch cover, this yield is much lower at 4%, multiplying the incoming cost by 25.

The yield means dividing the incoming environmental cost by 0.28, which almost quadruples it. For a domed watch cover, this yield is much lower at 4%, multiplying the incoming cost by 25.

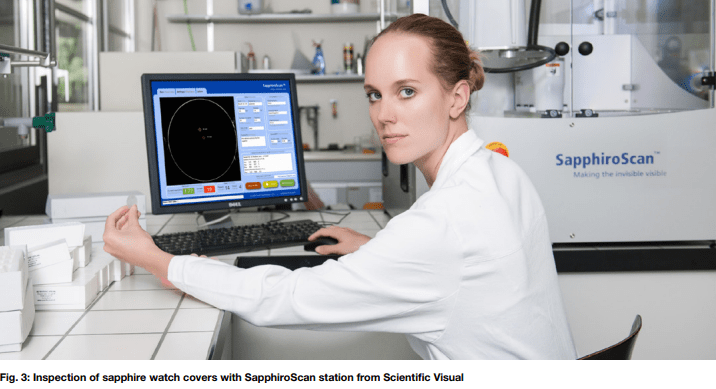

These steps can all be optimised with digital quality

control from the Swiss company Scientific Visual.

The company manufactures scanners for quality

inspection of industrial crystals (Fig. 3). Using these

automated tools, individual steps can be optimised

to avoid defects. For example, it prevents defective

crystal parts from entering costly processing. In

addition, by providing feedback to crystal growers, fewer crystals will have to be scrapped. The

simulated form for the cylinder can be moved so that

a minimum of defects remain in the physical carrot.

Slicing can also be offset to bring defects between

adjacent wafers. These steps all work to bring the

yield for a flat cover to 34%. For a domed watch

cover, the improvement is from 4% to 5%, which is a

25% improvement.

These steps can all be

optimised using digital

quality control from the

Swiss company Scientific

Visual

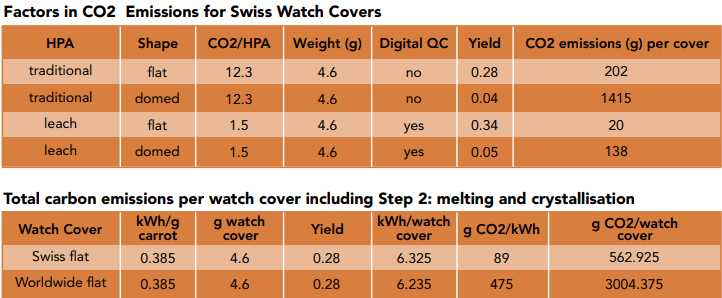

Let’s see what the numbers show. In the worst-case

scenario, HPA emits 12.3 grams of CO2 per gram of

HPA. Manufacturing our flat watch cover emits:

12.3 x 4.6g /0.28 yield = 202g

And the domed watch cover emits:

12.3 x 4.6g /0.04 yield = 1.4kg

These numbers show why crystal sapphire has been

called the “black sheep of watchmaking”. (7)

The use of current low-emission HPA and digital

quality control reduces these values to 20g and

138g, respectively. This is even before zero-emission HPA eliminates the cost completely, if not

the wastage. The table above shows that the CO2

emissions can be reduced by 22%.

Conclusion

We have seen that the environmental cost of a watch

cover can be very high if one does not think about it.

Through attention to detail at all process steps, it can

be reduced to that from melting the HPA and running

the machines if their power sources are not green.

This can be applied to other markets and use cases

for sapphire, such as LEDs and other applications.

We will discuss these cases in a future article.

References

1. https://momentumwatch.com/blogs/momentum-blog/whats-the-benefit-of-sapphire-crystal-sapphire-vs-mineral-crystal

2. https://www.innovationnewsnetwork.com/high-purity-alumina-sustainably-produced/29593/

3. “Scientific_Visual_Eco-audit-watch-sapphire_article” at https:// scientificvisual.ch/

4. https://www.imarcgroup.com/watch-market

5. https://www.sueddeutsche.de/wirtschaft/rolex-luxusuhren-1.5777888

6. “Scientific_Visual_Eco-audit-watch-sapphire_slides_SSC_29_ Sept_20222” at https://scientificvisual.ch/

7. “LeTemps_ScientificVisual_22_Oct_2022” at https://scientificvisual. ch/