Engineering brilliance:

HPA sapphire a platform

for LED production

High purity alumina sapphire has many benefits that make it a vital component in LED production

Giant LED displays light up New York’s Times Square. © Pexels, Marcus Herzberg

HIGH purity alumina (HPA) is a material you may

not have heard of, but it is an important ubiquitous

component of our daily lives. It is the primary

ingredient in the production of sapphire crystals,

which are fundamental to light-emitting diodes

(LEDs) – small light sources that illuminate everything

from our personal devices to our cities.

The demand for HPA is on a steady rise owing to the

increase in demand for sapphires, driven by the LED

industry. The value of sapphires as a material for LED

production can be condensed into the following four

key reasons:

Firstly, sapphire shares a similar crystal lattice

dimension with gallium nitride (GaN), the primary

material used in the creation of high-brightness blue

and white LEDs. This lattice compatibility results

in fewer structural defects, thereby enhancing the

efficiency of the LED production.(1)

Similarly, transparency is another crucial feature,

ensuring the light generated faces no obstruction

from the LED’s underside, giving sapphire an

advantage over silicon as an LED substrate.

Moreover, sapphire’s high thermal conductivity is

vital for LEDs, which generate heat during operation.

Efficient heat dissipation is necessary to prevent damage to the LED structure and maintain its

lifespan and efficiency.

Lastly, sapphire’s superior electrical insulation

properties allow it to effectively insulate the active

parts of the LED from other components, reducing

the risk of electrical short circuits.

The journey from high purity alumina to an LED

is complex and fascinating, involving a blend of

chemistry, engineering and precision manufacturing

that often spans across international borders.

The genesis: High purity alumina

The production chain commences with HPA – a

superior-grade aluminium oxide (Al2O3) powder,

produced with a focus on purity. 4N HPA (99.99%

pure) is typically employed for LED applications,

while an even purer variant, 5N HPA (99.999% pure),

is used for optics.

The purity of HPA is not merely a number, it’s the

cornerstone of successful LED production. Even

the slightest impurity can induce defects in the final

product, impacting the performance and efficiency of

the LEDs.

LED production, for example, is very sensitive to

the effects of Low Angle Grain Boundaries (LAGBs) – small crystal grains in the sapphire wafer that are

misaligned compared to the main wafer volume.

They reduce adhesion and compromise the structural

quality of the epitaxial layer deposited on the

sapphire wafer, reducing LED device performance.

The purity of the HPA has a direct influence on the

occurrence of such defects.

Another factor that is becoming increasingly

important for HPA users is maintaining a green

supply chain with no carbon emissions.

In the quest for a high-purity and environmentally

friendly high purity alumina, companies like

Advanced Energy Minerals, based in Cap-Chat,

Québec, Canada, (Fig. 1 ) are leading the way. The

company sources raw material exclusively from

hydropower and is committed to 100% green HPA

production, powered exclusively by green energy

from Q3 2023.

The birth of sapphire crystal: A process of precision and patience

The production of synthetic sapphire crystals, known

as ‘boules’, from HPA powder or monoliths is a

complex process where size matters.

Sapphire boules serve as the starting material for

thin wafers (250-150 µm) that later become LED

substrates during production. The diameter of the

finished LED wafers is determined by the size of

the boules. This diameter can range from 2” (almost

obsolete now) to 6-8” (common today) to 12” (future

standard).

Competition requires growing larger boules, which is

more economically viable.

For context, a 90kg boule that accommodates an

8” core diameter, has a bottom diameter of 30cm

and stands at 45cm tall. The largest sapphire boule

produced at the time of writing is 800kg and measures

70-80cm tall. It was manufactured in China (Fig. 2).

Growing such boules demands precision, expertise, and time. The LED sapphire is often produced using the Kyropoulos growth method,(2) which allows the largest crystals of the highest quality to be produced.

The process begins with a slightly imperfect sapphire seed coming into contact with high purity alumina melt at around 2,050°C (3,686°F). As the crystal grows, it is surrounded by the melt and continues to grow until its surface reaches the crucible walls and gets lifted to restart the growth cycle. This method allows crystallisation at low temperature gradients, resulting in lower thermal stresses in the crystal.

Growing such boules demands precision, expertise, and time. The LED sapphire is often produced using the Kyropoulos growth method,(2) which allows the largest crystals of the highest quality to be produced.

The process begins with a slightly imperfect sapphire seed coming into contact with high purity alumina melt at around 2,050°C (3,686°F). As the crystal grows, it is surrounded by the melt and continues to grow until its surface reaches the crucible walls and gets lifted to restart the growth cycle. This method allows crystallisation at low temperature gradients, resulting in lower thermal stresses in the crystal.

Sapphire growth requires an experienced operator

who is trained for several months. For a 90kg boule,

the process takes 17 days – 8.5 days to grow the

crystal and another 8.5 days to cool it down, and for

800kg it is far more than a month.

Sustainability is also a key component of this

process, as the crystal-growing furnace can

consume 200 kW of electricity or even more.

Sapphire manufacturer Alox Technology, based in

Washougal, Washington State, uses hydroelectric

power from the nearby Columbia River for the

crystal growth. This is an example of how the LED

industry not only produces products with low power

consumption but also promotes environmental

sustainability.

Diving deeper: The art of coring and wafering

The growth of a boule is merely the beginning of the

journey. For the boules from Alox Technology, this

journey leads from the West Coast of the US to Riga,

Latvia.

In order for the boule to become a LED substrate,

it must first be processed into a cylindrical core, or

‘cored’.

But before that, it must be ensured that the parts of

the boule volume that are used for wafer production

are free of defects such as small bubbles, cracks,

and impurities. This is where the company Scientific

Visual from Switzerland come in, offering advanced

crystal inspection equipment.

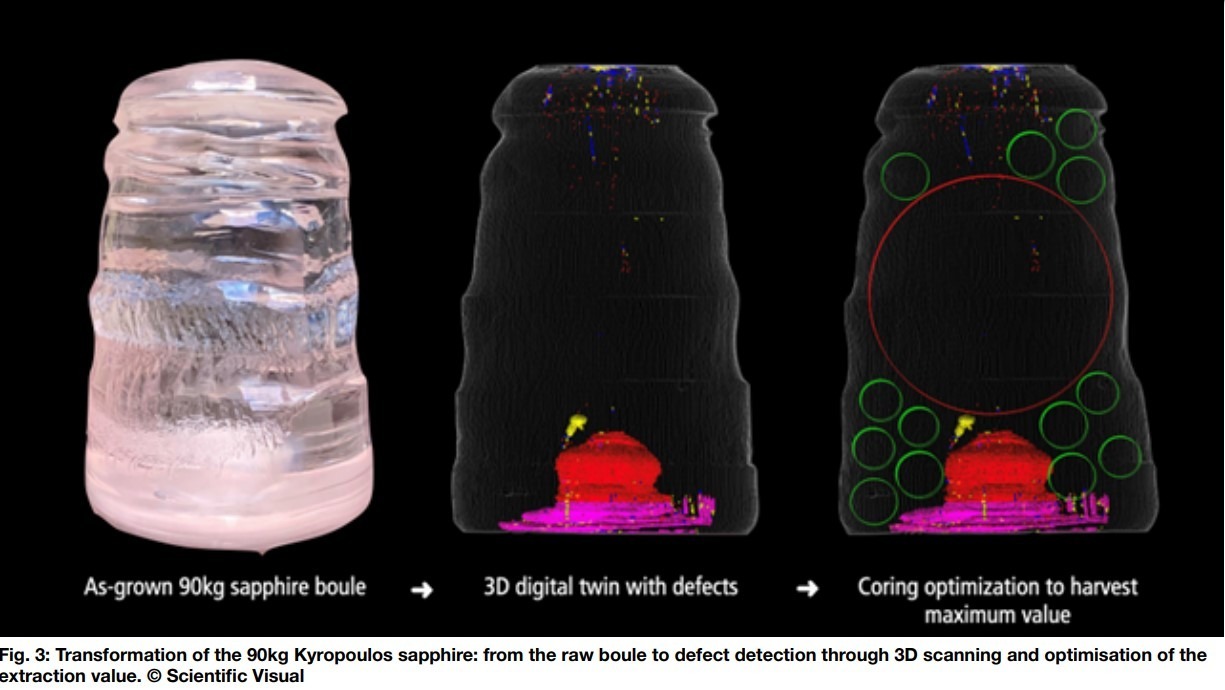

Scientific Visual’s fully automated four-axis scanners inspect large sapphire boules and detect internal

defects with an accuracy down to 8 µm. These

scanners can identify bubbles, structures, clouds,

and other yield-impacting defects and encode them

in a 3D model called a digital twin. This digital twin

enables computer-aided optimisation to determine

the defect-free zones that are most suitable for

processing (Fig. 3 ). This maximises yield in both the

coring and wafering processes.

For example, if there are few defects in an extracted

core, their positioning relative to the wafering

system is important. If you know the exact defect

co-ordinates, you can calculate a core offset in

the wafering machine to position more defects in

the saw gaps and outside the future wafers. Such a

defect-aware wafering approach, known as Smart

Wafering, enables up to a double-digit increase in

defect-free wafer production without the need to

grow or buy new boules.(3) The only prerequisite for

this is a high-precision digital twin of the crystal.

After coring, the extracted cylinders are ‘wafered’

into thin slices that are about 300-800 microns

thick, depending on the diameter. Sapphire has a

hardness just below that of diamond, so diamond

saws and considerable energy is used for cutting and

wafering. The wafers are then further refined through

processes such as grinding and polishing to prepare

them for the next phase of their life in an LED.

After coring, the extracted cylinders are ‘wafered’

into thin slices that are about 300-800 microns

thick, depending on the diameter. Sapphire has a

hardness just below that of diamond, so diamond

saws and considerable energy is used for cutting and

wafering. The wafers are then further refined through

processes such as grinding and polishing to prepare

them for the next phase of their life in an LED.

The finishing touches: From wafer to LED

After the rigorous process of inspecting and cutting,

the sapphire boule is transformed into thin wafers

that serve as the LED epitaxy. Each wafer is placed in a chamber heated to 900°C to grow the light-emitting

layers on it, taking advantage of the sapphire’s hightemperature stability.

The LED layers are usually made of GaN, AlGaN

and InGaN. These materials have thermal expansion

coefficients and chemical resistances that must

be very similar to those of the sapphire wafer. The

interfacing of sapphire and light-emitting layers is the

result of years of research and development.

After growing the LED layers, the wafer goes through

a series of steps such as lithography, masking and

etching to bring the individual units, the so-called

‘dies’, to the desired size, followed by the application

of electrical contacts. The LEDs are then sawn and

packaged and mounted directly on an electronic

circuit board.

Throughout the whole process, precision is key.

Every step, from the creation of the high purity

alumina to the final LED production, has an impact

on the quality of the final product. As we move

towards the production of smaller devices such as

micro-LEDs, these steps need to become even more

precise to match the miniaturised dimensions.

With that miniaturisation, the industry is facing

stricter standards for the final products. This

ripple effect on the end products gets to the first

production steps, such as high purity alumina

production.

The future of HPA and LED production: Lighting the path forward

The world of LEDs is not static; it’s continually

evolving and improving. The evolution goes to

smaller devices with higher brightness.

A close relative of the LED, the miniLED, is

characterised by its smaller size. A miniLED

measures between 100 to 200 micrometres on a

side,(4)

which, while smaller than a typical LED, still

packs a powerful punch in terms of brightness and

efficiency.

The future of display technology is often associated

with microLEDs. Although they currently find a

home primarily in high-end displays due to their high

production costs, their potential is immense.

Each subpixel (or diode) in a microLED display is

individually controlled, emitting light without a backlight,

similar to an OLED display.(5)

Sizes of microLEDs

can range down to 3 µm, with a typical microLED

measuring around 10 µm. To put that into perspective,

a human hair is typically 70 +/- 20 µm thick.(6)

The LED industry is a dynamic and rapidly evolving field, with new technologies and applications

emerging regularly. As the demand for more efficient,

brighter, and smaller light sources continues to grow,

the role of HPA and sapphire in the LED industry will

only become more critical.

In 2022, the projected total volume of high purity

alumina was approximately 35,000 tons, with

a substantial 30,000 tons designated for LED

production.

Looking ahead to 2025, the demand for HPA

is expected to rise to 58,000 tons, with LEDs

accounting for a significant 49,000 tons, or an

impressive 84% of the total. By 2028, the demand

for LEDs is forecasted to reach a remarkable 85,000

tons.(7)

In essence, LEDs have been and will continue to be,

a crucial market for HPA, even as new applications

emerge and other markets expand.

As for sapphire, the global market for these crystals

attained a value of $903.3m in 2021, according to the

IMARC Group. They anticipate this figure to escalate

to $2,471.4m by 2027, with a CAGR of 18.5% during

the period from 2022 to 2027.(8)

Authors

• Richard Foster, Advanced Energy Minerals Inc.

• Mark Fearns, Advanced Energy Minerals Inc.

• Lauris Dimitrocenko, Alox Technology

• Ivan Orlov, Scientific Visual

• Caroline Chèze, Scientific Visual

• Mark Fearns, Advanced Energy Minerals Inc.

• Lauris Dimitrocenko, Alox Technology

• Ivan Orlov, Scientific Visual

• Caroline Chèze, Scientific Visual

References

1. Chao, Yeh, Wu, Kawagashi, Hsu, RSC Adv., 2020,10, 16284-16290 at

https://pubs.rsc.org/en/content/articlelanding/2020/ra/d0ra01900c

2. https://www.substech.com/dokuwiki/doku.php?id=synthetic_

sapphire#kyropoulos_method

3. https://www.youtube.com/watch?v=WFowrwiCnvo

4. https://encyclopedia.pub/entry/11217

5. https://www.radiantvisionsystems.com/blog/microled-cusp

6. https://wowskinscience.com/blogs/news/how-thick-is-human-hair

7. microled.info.com – 2022; Emergen Research – LED report 2022; CRU

Research – HPA Report 2021

8. https://www.imarcgroup.com/sapphire-glass-market, 2021