The Decarbonization Of The Chemical Sector

Fariba Safizadeh R&D at Advanced Energy Minerals, Dante Maestre Market Intelligence Manager at Advanced Energy Minerals, Mark Fearns* Technical Marketing Manager at Advanced Energy Minerals,

*author to be contacted for information and enquiries.

The chemical industry ranks among the world’s largest sectors, boasting an annual

revenue of around $4.7 trillion. Moreover, its products play a crucial role in the extensive global value chains, including those in manufacturing and construction. At the same time the chemical sector holds the unenviable record of being among the largest responsible for CO2 emissions into the atmosphere, which is why it is imperative to introduce modern and effective processes to limit environmental impact as much as possible.

Though the liquid electrolyte battery industry has seen a meteoric rise with the development and

implementation of lithium-ion batteries, at a rate almost unprecedented in peacetimes, the solid-state

sector is yet to yielThe urgency to reduce the use of chemical processes that generate high levels of CO2

emissions becomes apparent when considering a few key statistics. For instance, various

industrial subsectors contribute significantly to the overall CO2 emissions: petrochemical

and refineries make up 6.21%, iron and steel account for 5.06%, cement represents 4.14%,

fertilizers contribute 1.15%, lime and plasters make up 0.92%, paper and pulp contribute

0.92%, inorganic chemicals account for 0.46%, and other subsectors constitute 4.14%.d the same level of widespread commercial success despite the growing scientific and

public interest. In this issue of the AEM Newsletter, we explore where the solid-state battery status is at

and what still needs to be done before we can all enjoy safe, 1000km range vehicles.

A conventional lithium-ion battery (Figure 1) is composed of a lithium-based inorganic complex as a

cathode active material (CAM), such as litGovernments have explored various strategies to incentivise chemical companies to

develop more efficient and environmentally friendly processes. One such strategy is the

proposal for internal carbon pricing, which has multiple intended purposes. It serves as

an incentive and raises awareness about the necessity of reducing carbon emissions.

Additionally, it aids in strategic planning by allowing companies to assess the comparative

profitability of various investments in the event of a national carbon tax being

implemented. This approach has gained popularity in recent years. According to a survey

conducted by CDP, over 2,000 out of nearly 6,000 companies surveyed either already

utilised an internal carbon price or had plans to implement one within the next two years.

Another approach, known as “internal trading,” bears resemblance to government-operated cap-and-trade systems. In this method, companies have the ability to allocate

carbon credits to various business units, which can then trade these credits among

themselves should they exceed their emissions reduction targets. Conversely, some

companies impose a “carbon fee” upon their business units, with a predetermined

monetary value aimed at encouraging initiatives that reduce emissions, such as improving

energy efficiency. The funds generated from these fees can be directed toward

investments in renewable energy supplies or carbon offset programs.

hium iron phosphate (LiFPO4) or lithium oxides containing cobalt

and/or manganese; an anode typically based on graphite or silicon-carbon materials; a polymeric

separator material to regulate the ionic flow and prevent a short circuit; and an electrolyte (liquid or

polymer based) used to facilitate the flow of lithium ions.

From a more technical point of view, when it comes to decarbonisation, there are basically

4 approaches taken by the chemical companies that are listed in figure 1.

Fig. 1

The most effective is obviously the use of CO2 as reagent/feedstock in industrial chemical

reactions. The challenges associated with the conversion of CO2 are primarily related to

both its kinetic and thermodynamic stability. CO2 cannot be converted into commodity

chemicals or fuels without significant inputs of energy and contains strong bonds that are

not particularly reactive. As

a consequence, many of the

available transformations

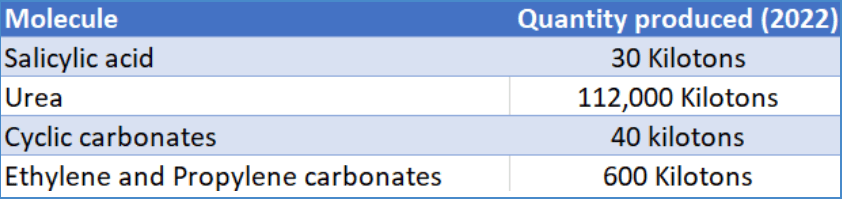

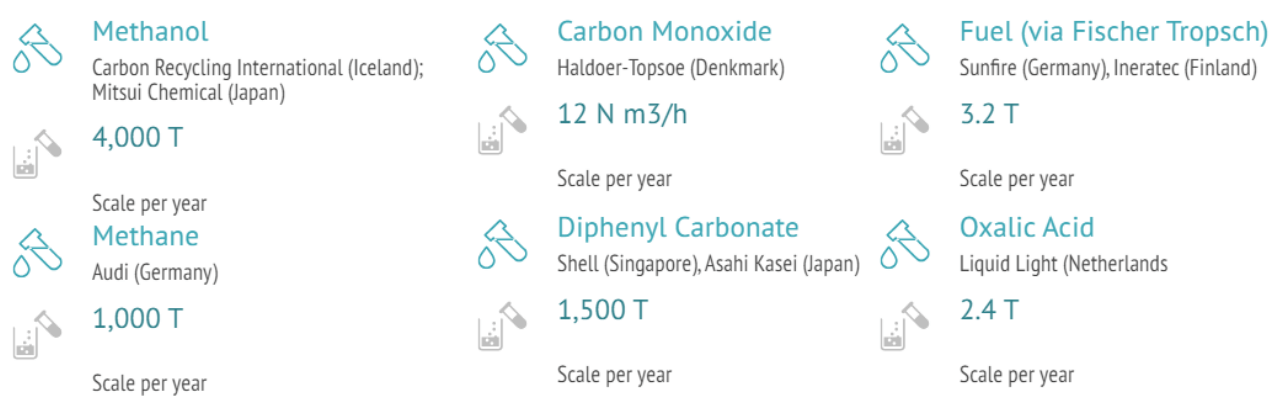

of CO2 require stoichiometric amounts of energy-intensive reagents. Table 1 list some of the major

commodity chemicals that are currently synthesized from CO2 on an industrial scale

globally, whose global production exceed the 150,000 kilotons. Table 2 instead listed

some of the major fine and commodity chemicals that are currently synthesized from CO2

on a pilot plant scale. It is worth to mention that the companies active in these sector are

spread across three continents and are in most case multinational companies.

Table 1

Another effective approach taken by the chemical companies to reduce their carbon

footprint has been the use of more efficient process less energy intense. In particular

many companies have devoted a lot of efforts to optimize the steam generation process

with the introduction of heat pumps that transfer energy from a low temperature source

to a high temperature. This works with a coolant that evaporates in a circuit under low

pressure by adding heat – from the plant or used cooling water. The gas is then

compressed by a compressor. It condenses and gives off useful heat. Then the cycle starts

all over again.

Table 2

If heat pumps and compressors are operated with electricity from renewable sources, the

entire process is climate-neutral, thus without CO2 emissions. By using waste heat from

chemical plants and cooling water systems to generate much of the steam big companies

use in production, heat pumps are drastically reduce the need for fossil fuels.

However, decarbonising the chemical industry requires changes in technology through

low-carbon innovations identified in the previous sections and a broader sociotechnical

transition that entails changes in behaviour, culture, policy, industry strategies,

infrastructure, and science. To accelerate and bring the transition toward the

decarbonisation process in energy-intensive processing industries, more insight into the

sociotechnical barriers that hinder the transition process is needed.

Another aspect of the decarbonization of the chemical sector is the introduction of

feedstock from biomasses. In fact, using renewable raw materials helps to save fossil

resources and contribute to reducing greenhouse gas emissions. Moreover it has been

observed that customers are increasingly interested in products based on renewable raw

materials as they are often perceived as healthier, more natural and having a positive

environmental impact. Last, but not least the use of renewable raw materials broadens

raw materials basis and thus reduces the dependency on fossil resources.

An interesting example in this sense is the German group BASF that in 2021, has

purchased around 1.3 million metric tons of renewable raw materials. These renewable

raw materials are derived from various value chains, vegetable oils, fats, grains, sugars

and wood.

A very positive aspect is the fact that now all the big multinational companies are

reporting the tons of CO2 produced. Particularly interesting are the cases of BASF and

Dow which are respectively #1 and #2 in the ranking of the chemical industry, that are

reporting since 2021 the CO2 emissions reduction in their quarterly financial reports for

investors.

According to the IEA, direct CO2 emissions from primary chemical production remained

still relatively constant at around 935 million tons in 2022, as a result of a stagnation

in production. This is in tandem with a relatively stable primary chemicals CO2 intensity

over recent years, at around 1.3 tons of CO2 per tonne of primary chemicals1. The

chemical sector is the largest industrial energy consumer but only the third largest

industry subsector in terms of direct CO2 emissions. Ammonia production is responsible

for the highest share of emissions accounting for 45% of emissions from primary

chemical production, followed by methanol (28%) and high-value chemicals (27%). The

IEA also provides a chart of global CO2 emissions by sector from 2019 to 2022, where you

can see the relative contribution of the chemical sector compared to other sectors.

In summary, achieving a full decarbonization of the chemical sector remains a formidable

challenge. However, it’s encouraging to note the availability of processes and technologies

that can contribute significantly to meeting these vital objectives. Furthermore, there is a

growing awareness throughout society at all levels regarding the need to support chemical

companies in their efforts to reduce emissions. This is precisely why many companies

have established ambitious targets in this regard.